Category

Pipe Fitting Connector Mould

PPR pipe fitting is specially for water supplying piping system, the connection of the fitting with the pipe has 3 diffe

Basic Info.

| Model NO. | JMT2020135 |

| Application | Home Use |

| Runner | Hot Runner |

| Design Software | UG |

| Installation | Fixed |

| Certification | TS16949, ISO |

| Standard | HASCO |

| Customized | Customized |

| After-sales Service | 1year |

| Huangyan | Jmt -Technology |

| Transport Package | Wooden Case |

| Trademark | JMT Technology |

| Origin | China, Zhejiang, Taizhou |

| HS Code | 8480710000 |

| Production Capacity | 650 Set/Year |

Product Description

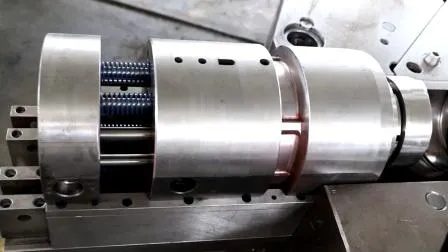

Mould Name: PPR Pipe Fitting Mould Product Size: 1/2" Product Description: PPR elbow Mould Cavity: 24 cavities Mould Size: 450x500x480mm Suitable Machine: DKM-250 Ton Mould Main Material: 718H Mould Injection System: Cold runner Mould Ejection System: ejector pin Mould Cycle Time: 35 Seconds Mould Running: 1M Delivery Time: 45 working days Mould Features: The technical points for PPR pipe fitting moulds. 1. how to avoid the shrinkage marks on the fitting. 2. how to increasing the injection molding speed. 3. how to realize the cavities and cores interchangeable. 4. if there are metal bolt or nuts

PPR pipe fitting is specially for water supplying piping system,

the connection of the fitting with the pipe has 3 different types.

1. gluing type.

2. welding type.

3. screwing type.

Based on the function, we divided the PPR pipe fitting mould into below 4 different types.

A.norml PPR pipe fitting mould

B.Self welding PPR pipe fitting mould.

C. PPR pipe fitting mould unscrewing ejection.

D. PPR metal over molding pipe fitting mould.

Zhejiang JMT Technology Co.,Ltd specializes in designing and making auto parts, home appliance, kids electric car and household moulds. From 2005 until today, JMT Mould has had many great achievements in plastic mould development and manufacturing. Today, JMT Mould has over two hundred workers, including a mold design team of over 42 engineers. JMT Mould has organized their facility for efficiency using the latest principles of lean manufacturing. Their capabilities now include prototyping, an injection workshop and a state of the art QC lab. To help realizing the benefits of consistent quality systems and business practices, JMT Mould invested the time and effort to be awarded the ISO/TS 16949: 2009&tISO9001-2015 Quality Certification.JMT Mould has grown into a superior mold manufacturer with a strong engineering team. Engineering work includes not only mold designs, but also mold feasibility, mold flow, product design expertise and prototyping services. These allow the most efficient mold strategies to be developed for our customers. We have developed great relationships with customers such as VALEO, MAHLE GROUP, GOODBABY GROUP, by always providing excellent service. We are proud of our culture of continuous improvement and welcome all customers and potential customers to visit our factory anytime.

Q1:How do you need to quote?

We can quote a rough price with picture, but to get an accurate price, please offer the following

information:

1. 2D and 3D (format:CAD/PDF/DWG/DXF/DXW/IGES/STEP etc.)

2.Material

3.Quantity needed

4.Surface treatment

5.Any special pacaking or other requirements

Q2:What's the MOQ?

We can accept low quantity.

Q3:Can I get a sample for check?

Yes, just need sample cost and shipment cost,we will return it back in mass production.

Q4:Can you design product for me if I only have a rough concept ?

Yes! We can also offer design service as long as you tell us all your requires.

Q5:What's the leading time?

It depends on quantity.Generally 5-20 days after order confirmation..